Manufacturing is built on the key tenets of productivity, efficiency and minimizing risk. To further optimize these operating parameters, new innovations are essential. Industry 4.0 / smart manufacturing is that innovation, transforming manufacturing and bringing notable competitive advantage to early adopters. To fully realize the benefits of smart manufacturing, organizations need the edge to do three things: consolidate and simplify disparate infrastructure, ensure intrinsic security, and generate insights at the point of data generation. The Dell Technologies Manufacturing Edge Solutions provide, enable and accelerate Industry 4.0 capabilities to improve operational and business outcomes for manufacturers.

The opportunity, the challenge

Manufacturing is ripe with incremental opportunity. Fueled by the promise of Industry 4.0, the Industrial Internet of Things (IIoT) is deemed one of the fastest growing and largest edge and IoT segments, forecasted to grow to US $949 billion by 2025.

By 2025, Industry 4.0 is forecasted to grow to US $949 billion.”

Forecasts predict that by 2025 there will be:

-

- 6 billion connected devices

- 79 ZB of data

And by 2027 we will achieve a $43 billion Global Edge computing market size.

This growth is spurred by novel competencies needed in manufacturing. IIoT’s edge computing capabilities can enable greater transparency into processes and then act on that information locally and autonomously.

Accelerating this shift toward data-driven, scalable and adaptable smart manufacturing are security requirements and the need to process volumes of data. Today, manufacturing environments are hindered by legacy infrastructure, network issues, data silos, integration challenges, and piecemeal solutions spanning a diverse sprawl of disconnected hardware, software, and processes. Manufacturers that move quickly to consolidate disparities will reap both short- and long-term rewards.

To leverage Industry 4.0, manufacturing’s inherent infrastructure challenges must be overcome. Smart manufacturing cannot be built or scaled on a foundation comprised of legacy systems and fragmented approaches. Here’s where Dell Technologies Manufacturing Edge Solutions can help. These edge solutions are tailored around manufacturers’ unique needs to simplify and consolidate all manufacturing within a predefined infrastructure, making it easy to implement, use and scale edge initiatives across factories.

An edge revolution for manufacturing

The Dell Technologies Manufacturing Edge Solutions are a fast ramp to smart manufacturing. With these solutions, manufacturers can get more aspirational with smart manufacturing goals to reduce unplanned downtime, minimize scrap production, and expedite diagnosis of equipment failures before they occur.

The Dell Technologies Manufacturing Edge Solutions are a ramp to smart manufacturing.”

The Dell Technologies Edge Manufacturing Solutions provide manufacturers a decentralized computing infrastructure with enhanced security and processing speeds. These solutions also combine the power of interconnectivity to leverage automation, machine learning and real-time insights, generated immediately and at the point where data is created and insights are used.

By offering the flexibility of capabilities via the cloud, providing best-in-class building blocks, and consolidating infrastructure, the Dell Technologies Manufacturing Edge Solutions drive IIoT transformation. The open architecture supports legacy transitions, offers multi-cloud capabilities and provides compatibility across manufacturing applications, making smart manufacturing simpler, easier and more flexible at the edge.

The solution

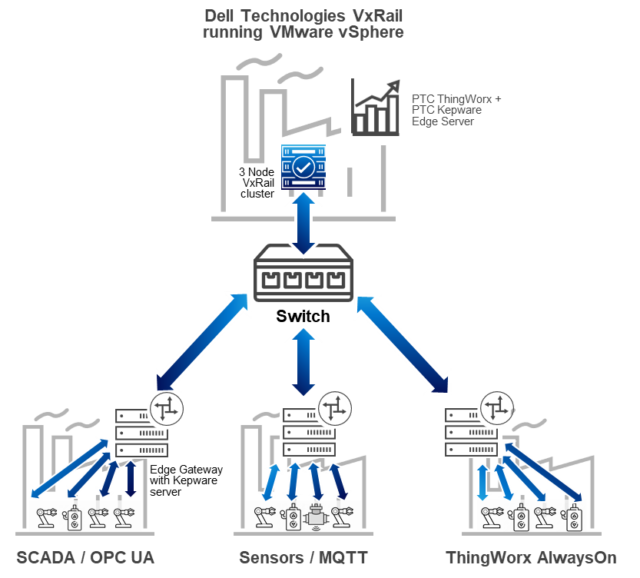

The Dell Technologies Manufacturing Edge Solutions consist of modular elements, which include an industry-leading HCI offering based on VxRail and proven manufacturing software support from PTC’s ThingWorx as well as collaboration with VMware, and others. The first in this portfolio of solutions is the Dell Technologies Manufacturing Edge Reference Architecture with PTC. It is also the first solution in the market offered with a subscription model based on APEX Private Cloud, allowing manufacturers to unleash the full potential of the edge with a single click, thereby enabling simplicity through consolidation, enhanced security and consistent life cycle management.

The Dell Technologies Manufacturing Edge Reference Architecture includes:

-

- 3-node VxRail with 50 Integrated Compute Block (ICB)

- Remote connectivity via Dell SD WAN

- Software support for PTC ThingWorx, VMware vCenter, ESX Hypervisors, and other partners’ software

- Offered through APEX Private Cloud, with a subscription model

Below is the general topology of the solution. You can more about this reference architecture here.

Key highlights:

- Unify disparate architectures via a “standardized” solution

- Enable scalability and speed

- Expand without the need to build alternate technology stacks

- Application-agnostic to allow multi-app integration

- Multi-cloud capabilities

- Secure solution built on trusted technology

- Fully supported solution, lifecycle of infrastructure managed by Dell

Why this solution is crucial in manufacturing

Manufacturers continually strive for improved operational outcomes. To manage costs and mitigate risks, goals include reducing unplanned downtime, minimizing scrap and predicting equipment malfunctions prior to failure. Solutions that provide the speed, scalability, agility and ability to leverage IIoT in pursuit of these outcomes is essential for progress.

Today, however, many manufacturers are running on legacy infrastructures which limits their ability to adopt new capabilities. It is common to see a plethora of “accidental architectures” vs. “intentional architectures” built in small batches as piece-meal solutions with limited connectivity options. Resolution requires infrastructure consolidation and simplification. This, in turn, will enable competencies such as virtualization, connected applications, AI / ML (artificial intelligence / machine learning), and operation-wide or enterprise-wide optimization.

With the Dell Technologies Manufacturing Edge Solutions, the concept of “fail-safe” operations can now be applied to IT / OT architectures. This helps mitigate significant vulnerabilities in production environments due to siloed data, modular architecture and disconnected applications. For example, if one piece of hardware fails, it can result in entire production line disruption, creating blind spots and costly consequences.

In addition, manufacturing-specific applications that are IIoT enabled — and their novel capabilities — are on the rise. These applications can deliver operational outcomes that significantly improve competitiveness and financial metrics. However, they require IIoT enabled environments. As one example, consider the predictive maintenance application call-out below.

Example: predictive maintenance

Unplanned downtime is the bane of all manufacturing. The cost of equipment failures skyrockets when it escalates into unplanned downtime, expanding into lost production, higher repair costs, missed revenue and other steep consequences. In some industries, such as automotive manufacturing, unplanned downtime is estimated to cost US $1.3 million per hour, creating an urgent need to mitigate this possibility. As a result, predictive maintenance applications — which warn of impending machine failure prior to them happening and at the lowest possible cost and risk profile — are increasingly recognized as a must-have manufacturing capability to both sustain and optimize profitable operations.

According to Gartner, predictive maintenance can generate cost savings of up to 40%. Enabled by IIoT, predictive maintenance benefits increase as fragmented systems and legacy infrastructure issues are resolved. For example, asset management via predictive maintenance can generate positive returns on a single asset. When predictive maintenance is applied to an entire operation or enterprise (requiring unified infrastructure at the edge), the breadth and magnitude of the benefits rise in-kind. The Dell Technologies Manufacturing Edge Solutions enable third party IIoT applications — such as predictive maintenance applications — ensuring intrinsic security, consistent life cycle management and generating insights at the point of data generation. These capabilities can translate into positive outcomes for manufacturers, regardless of company size.

With the announcement of the Dell Technologies Manufacturing Edge Solutions, Dell is expanding its commitment to manufacturing enterprises, empowering manufacturers to harness the power and promise of Industry 4.0 today. And, this is just the first step in a journey that Dell Technologies is taking together with manufacturing customers, partners and OT vendors. As IT and OT come together, Dell Technologies is dedicated to enabling seamless, intelligent, transparent infrastructure that will boost the confidence and capabilities to fully embrace this new manufacturing revolution.

Learn more

To learn more about the broad range of edge solutions, and how different industries are putting them to work to drive measurable results, visit DellTechnologies.com/Edge or enjoy one of 17 breakout sessions on edge and edge-related topics at Dell Technologies World.